Innovative Design and Integrated Manufacturing

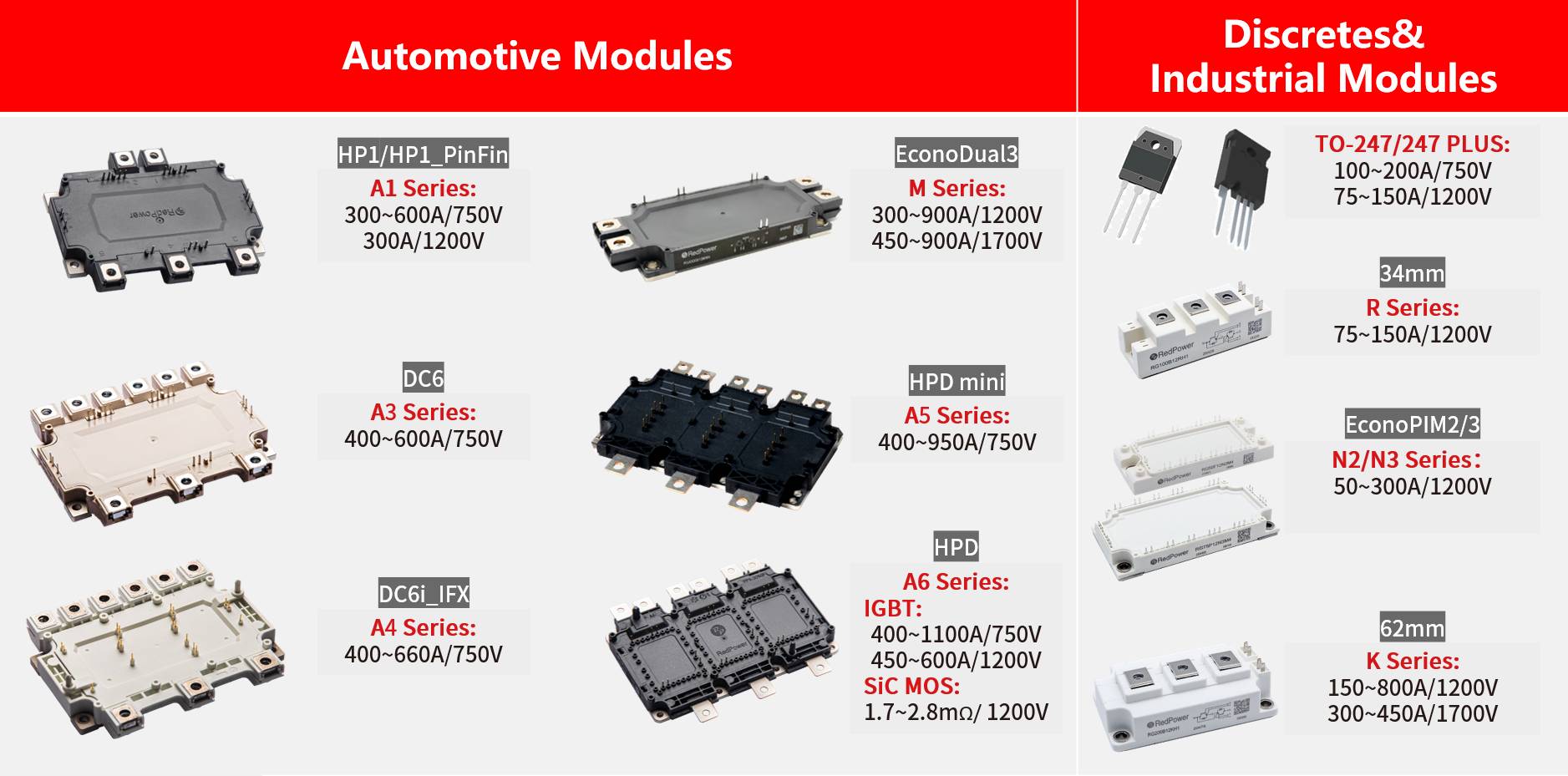

As an ODM (Original Design Manufacturer) for IGBT module packaging, our factory specializes in end-to-end solutions from conceptual design to mass production. We leverage advanced packaging technologies, including multilayer stacking, ultrasonic wire bonding (for copper/aluminum wires), and thermally optimized substrates (e.g., DBC ceramic bases), to enhance power density, thermal dissipation, and reliability. Our proprietary designs support customizable electrical layouts and mechanical structures, ensuring compatibility with automotive, renewable energy, and industrial applications.

Advanced Process Capabilities

Our manufacturing integrates automated processes such as vacuum reflow soldering, X-ray defect inspection, and laser marking, achieving precision in chip attachment, wire bonding, and encapsulation. We employ rigorous quality control, including thermal cycling tests and planar flatness verification, to meet AQG324/AEC-Q101 standards—critical for automotive-grade modules requiring failure rates <50 ppm.

Supply Chain Resilience and Customization

We address global supply chain challenges by offering pin-to-pin compatible replacements for leading international brands (e.g., Infineon, Mitsubishi), enabling seamless migration without hardware redesign. Our flexible production lines support rapid prototyping and scalable volumes, reducing clients' time-to-market by 6–8 months while cutting costs by 30–50%.

Comprehensive Support Ecosystem

Beyond manufacturing, we provide co-design collaboration, failure analysis, and thermal simulation services. Clients benefit from our expertise in electromagnetic compatibility (EMC) and protection circuits, ensuring modules operate stably in high-vibration environments like EVs and rail transit.

By integrating R&D, agile production, and lifecycle support, our ODM model empowers clients to navigate IGBT supply constraints while advancing performance frontiers.