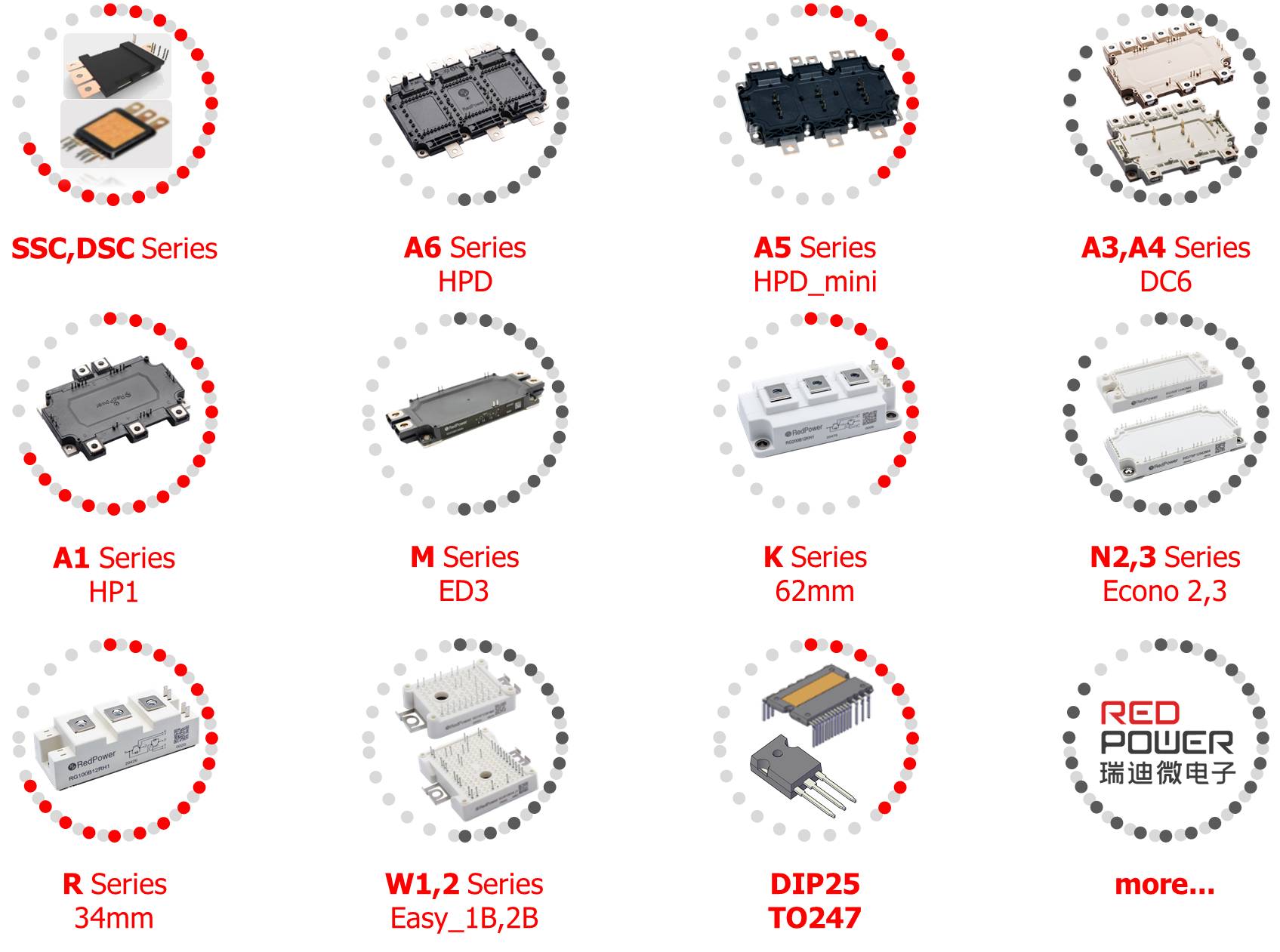

As a certified OEM (Original Equipment Manufacturer), our facility specializes in end-to-end IGBT module packaging and testing for global clients. We leverage automated production lines equipped with advanced processes such as vacuum reflow soldering, ultrasonic wire bonding, and X-ray defect inspection to ensure precision in chip attachment, interconnection, and encapsulation. Our manufacturing capabilities cover a comprehensive range of package types—including SSC/DSC,34MM,62MM,Econo2/3,Easy 1B/2B,EconoDual, and HP1/HPD/DC6 series—tailored for automotive, industrial, and renewable energy applications.

Adhering to IATF 16949, AQG 324, and AEC-Q101 standards, we implement rigorous quality control protocols. These include thermal cycling tests, planar flatness verification, and void-rate validation (<5% via X-ray screening) to guarantee module reliability under extreme conditions. Our OEM model supports pin-to-pin compatible designs, enabling seamless replacement for international brands (e.g., Infineon, Mitsubishi) without hardware redesign With flexible production scaling from prototyping to high-volume orders, we reduce clients’ time-to-market by 6–8 months while optimizing costs by 30–50%. Partner with us to navigate supply chain challenges and access resilient, high-performance IGBT solutions.

Certified for quality and scalability, our OEM services empower clients to focus on innovation while we deliver manufacturing excellence.